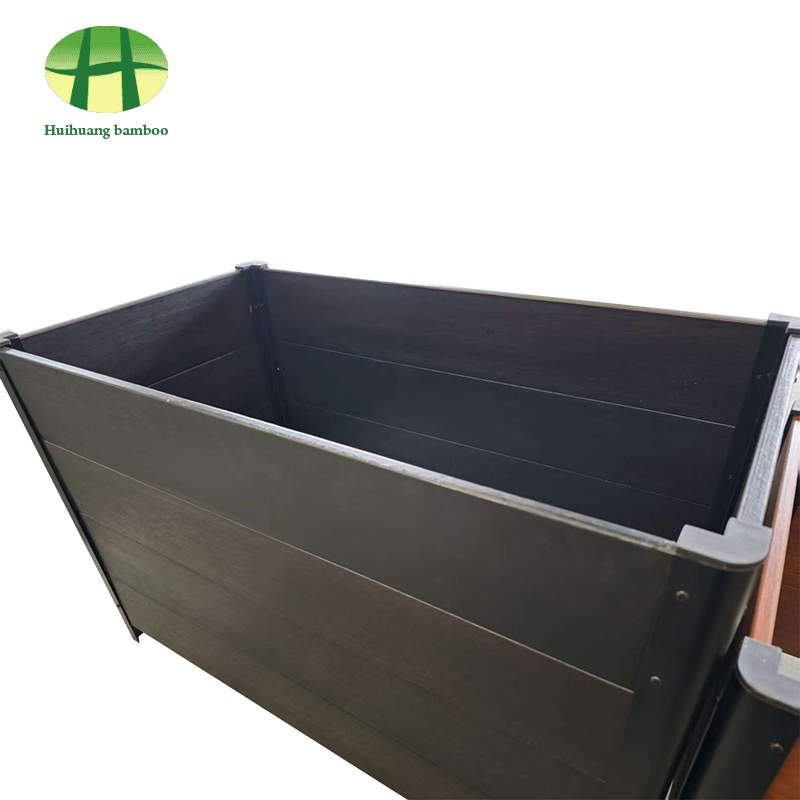

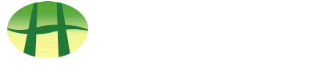

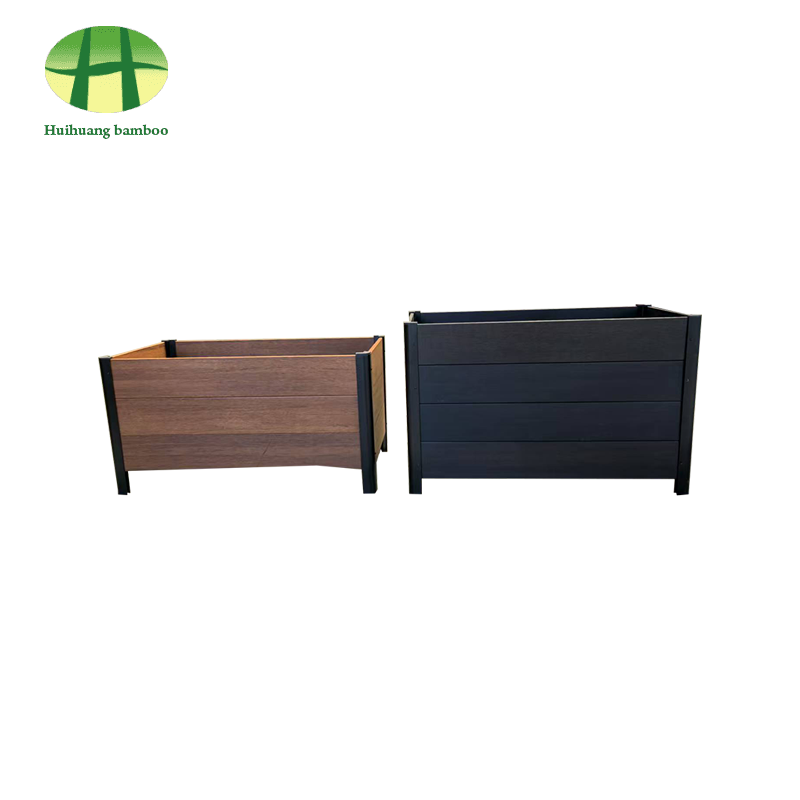

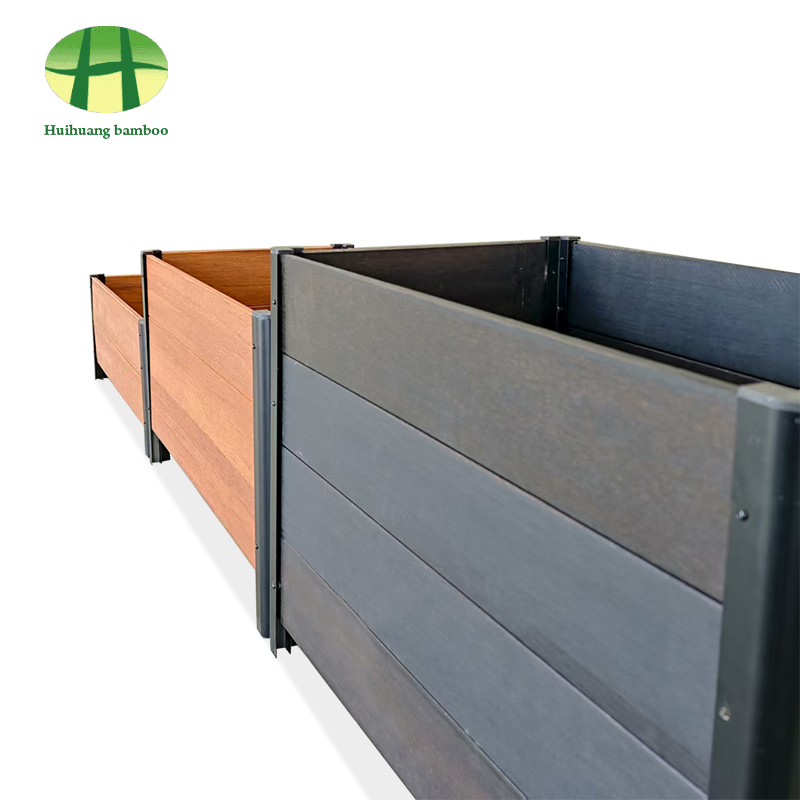

Outdoor weather resistance bamboo planter composite wood planter box - Engineered bamboo-wood composite for extended outdoor service life and modular landscape installation

Product Features

- Material composition:Made from a bamboo fiber and wood-plastic composite blend with polymer matrix and mineral fillers to provide dimensional stability and reduced moisture uptake.

- Weather resistance:Manufacturing process includes thermal consolidation and UV stabilization to limit surface degradation from sunlight, rain exposure, and freeze–thaw cycles.

- Serviceability and customization:Modular panel construction supports custom-size composite planter boxes, integrated drainage options, and joinery for multi-unit commercial landscaping installations.

Applications

|

This composite planter box is specified for environments requiring weather-stable planting solutions and adaptable sizing. Primary applications include:

|

Product Description

This outdoor weather resistance bamboo planter composite wood planter box is designed to provide stable containment for soil and vegetation in exterior environments. The product combines mechanically processed bamboo fiber with thermoplastic binders to form a composite board that retains the tactile appearance of natural wood while reducing susceptibility to rot and insect attack common in untreated timber. Design intent emphasizes predictable dimensional behavior, manufacturability for custom lengths and profiles, and compatibility with standard landscape installation practices.

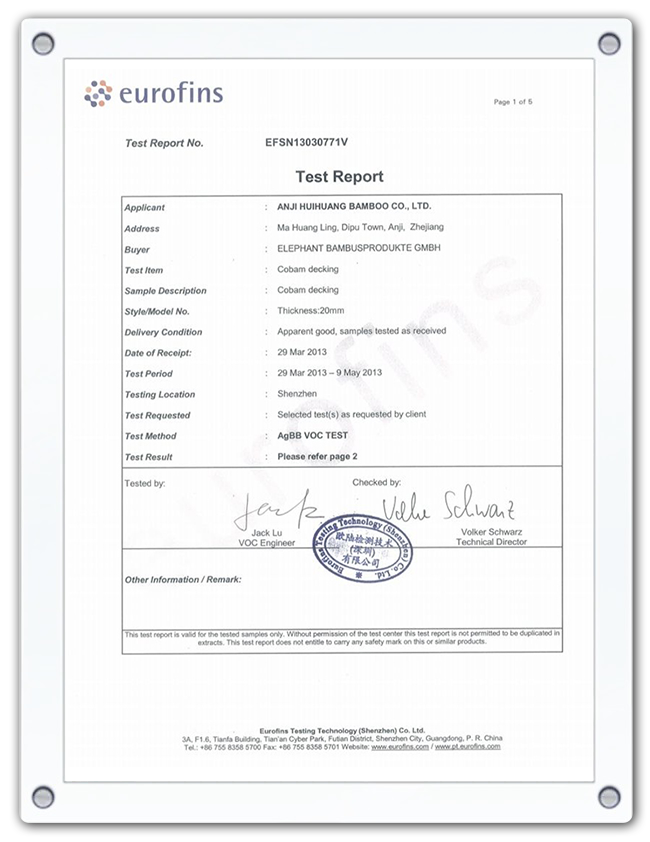

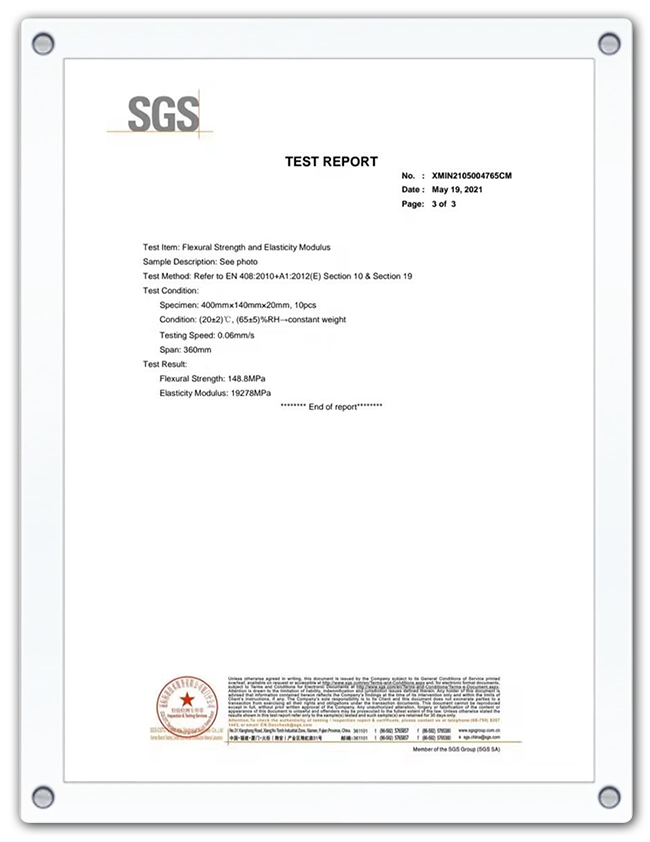

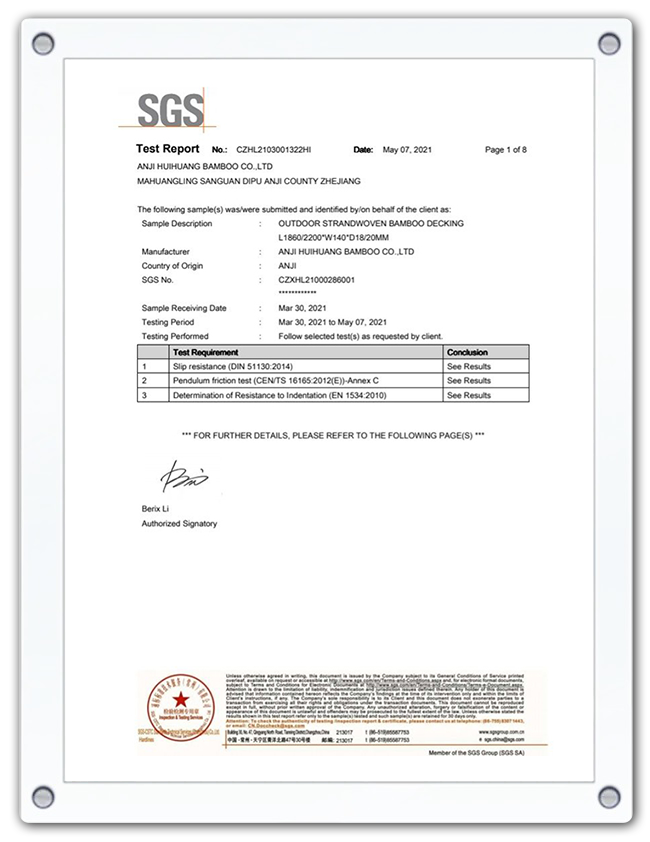

Production employs controlled thermal forming and compounding processes to achieve consistent density and moisture resistance. Surface profiles are available with textured grain replication or smooth finishes to match project specifications. Quality control follows factory inspection protocols for density, moisture content, and pull-through strength; additional performance attributes include resistance to biological decay and enhanced UV resistance engineered into the polymer matrix.

Technical Specifications

| Specification | Value / Option |

| Material | Bamboo fiber reinforced wood-plastic composite |

| Typical density | 900–1,200 kg/m³ (product-dependent) |

| Standard lengths | 600 mm, 900 mm, 1,200 mm; custom lengths available |

| Section profiles | Rectangular box, slatted planter, tapered planter |

| Surface finish | Textured grain replication / Smooth milled |

| Drainage options | Pre-drilled drainage ports, integrated liner channel, removable drain plugs |

| Color options | Natural bamboo tone, urban grey, dark walnut; custom color matching available |

| Installation method | Stackable modular units, through-bolt assembly, bracket mounts for raised decks |

| Expected maintenance | Periodic cleaning, inspect drainage annually, replace liner when required |

FAQ

1. What maintenance procedures extend the service life of a bamboo-wood composite planter box?

Recommended maintenance includes: regular removal of surface debris, periodic inspection and clearing of drainage ports to prevent water pooling, replacement or cleaning of internal liners to reduce soil migration into composite joints, and application of compatible surface sealants only if specified by the manufacturer. These practices reduce moisture retention and mechanical wear that accelerate material degradation.

2. How does this composite perform compared to untreated timber in outdoor conditions?

The bamboo-wood composite exhibits reduced water absorption and greater dimensional stability than untreated timber due to its polymer matrix and thermal consolidation. It does not rely on preservative chemicals to resist biological attack; instead, resistance to rot and insect damage is provided by the composite formulation and factory-applied stabilizers. Expected performance advantages include lower frequency of replacement and fewer site interventions for decay control.

3. Are custom sizes and integrated drainage available for commercial orders?

Custom fabrication options include non-standard lengths, bespoke cross-sections, integrated drainage channels, and pre-installed mounting brackets for large-scale landscape projects. Production lead time and minimum order quantities apply; technical drawings and site requirements should be submitted for a formal quotation covering tooling, finish selection, and delivery logistics.

English

English Deutsch

Deutsch

+86-572-5215066 5216895

+86-572-5215066 5216895 office@hh-bamboo.com

office@hh-bamboo.com East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.

East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.