- 1 I. Redefining Outdoor Decking Materials

- 2 II. Mechanical Performance Against Environmental Stress

- 3 III. Corrosion and Decay Resistance: The Role of Treatment

- 4 IV. Photodegradation and Surface Integrity

- 5 V. Quality Standards and Technical Sourcing for B2B

- 6 VI. Long-Term Performance of Strandwoven Bamboo

- 7 VII. Frequently Asked Questions (FAQs)

- 7.1 Q1: How does strandwoven technology specifically improve the bamboo decking outdoor patio's durability?

- 7.2 Q2: Is strandwoven bamboo decking temperature resistance better than wood? Why?

- 7.3 Q3: What is the main purpose of the bamboo patio flooring anti-corrosion treatment (carbonization)?

- 7.4 Q4: What maintenance is required for outdoor bamboo decking UV degradation prevention?

- 7.5 Q5: How does the durability assessment strand woven bamboo compare to pressure-treated wood?

I. Redefining Outdoor Decking Materials

Designing an outdoor space requires selecting materials that can withstand a relentless assault from the elements: intense UV radiation from prolonged sun exposure, corrosive moisture cycling from rain and snow, and the physical stresses of extreme thermal shifts. The traditional shortcomings of wood decking have led to the innovation of engineered materials. The bamboo decking outdoor patio solution, specifically using strandwoven technology, transforms natural bamboo fibers into a dense, durable material capable of delivering high performance and longevity in challenging outdoor environments. Ningguo Kuntai Bamboo and Wood Co.,Ltd., established in 2002 in the "Bamboo Village" of Ningguo, is a professional manufacturer dedicated to this high-performance category, producing strandwoven bamboo decking, wall-cladding, and other specialized products. Operating from our modern KUNTAI factory, which covers 30,000 square meters, we are committed to quality and innovation, evidenced by certifications like FSC, CE, and SGS, and proudly holding US Patent No. US11148318 for our outdoor bamboo decking technology.

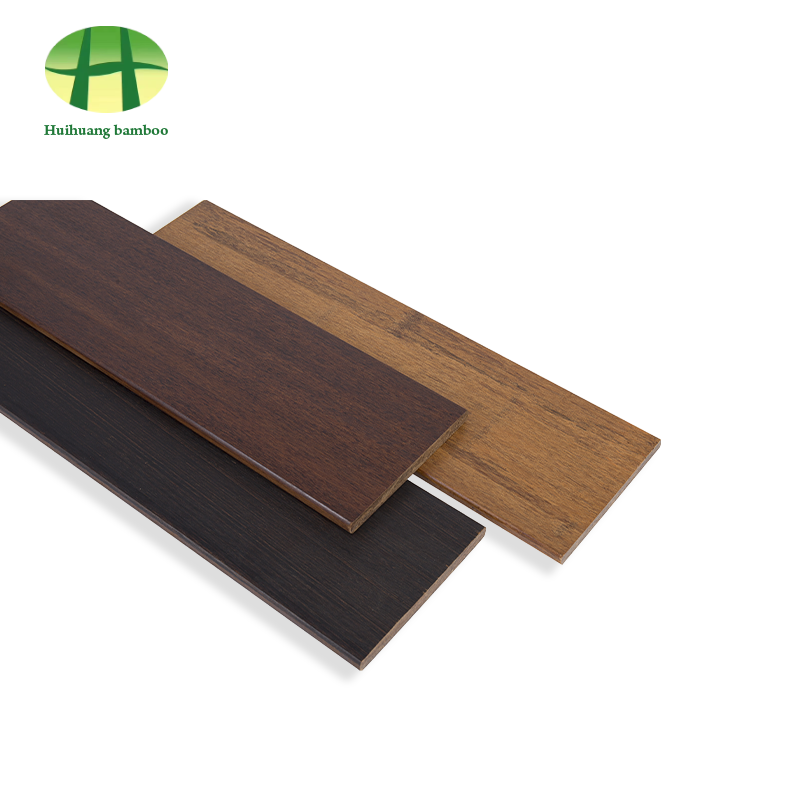

Custom size glossy heavy bamboo flooring

II. Mechanical Performance Against Environmental Stress

The mechanical integrity of outdoor decking is severely tested by temperature and moisture fluctuations. The unique strandwoven process is essential for creating a stable material resistant to warping and cracking.

A. Strandwoven Bamboo Decking Temperature Resistance

The strandwoven bamboo decking temperature resistance is superior to many solid woods because the process compresses the bamboo fibers with high-density resin binders. This extreme density (often exceeding 1,000 kg/m³) significantly restricts the material's ability to absorb water and, consequently, reduces the potential for volumetric swelling and shrinkage. This stability is critical for preventing the stresses that lead to structural failure during freeze-thaw cycles and rapid temperature shifts common in mid-latitude climates. Comparing dimensional stability under moisture changes:

| Decking Material | Density (kg/m³) | Swelling/Shrinkage Rate (Typical) | Warping Tendency Under Stress |

|---|---|---|---|

| Standard Pressure-Treated Softwood | 400 - 600 | High (5% - 8%) | High |

| Standard Hardwood (e.g., Oak) | 650 - 750 | Moderate (3% - 5%) | Moderate |

| Strandwoven Bamboo | > 1000 | Low (1% - 2%) | Very Low |

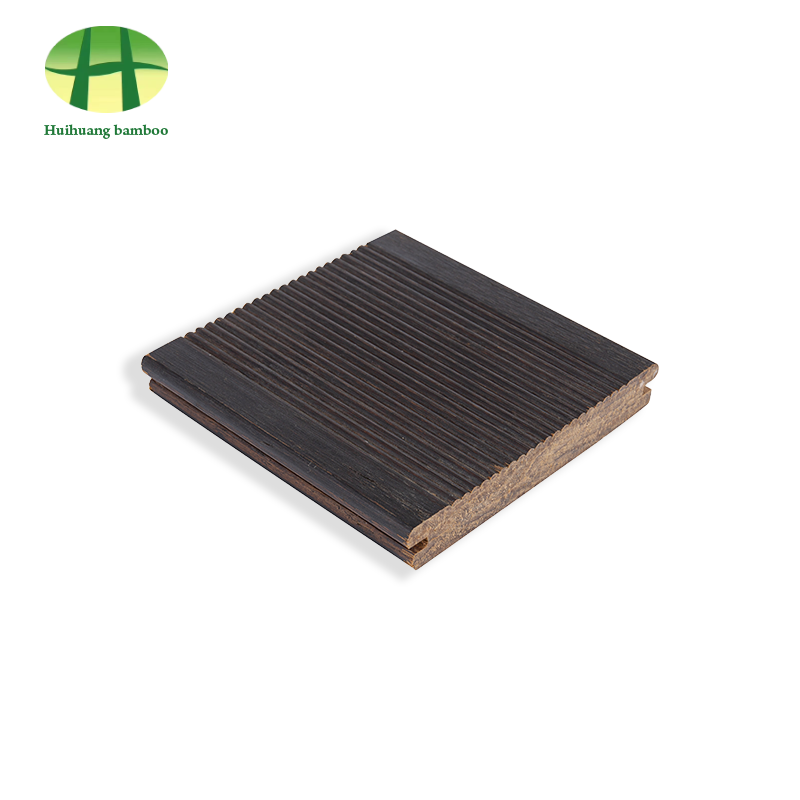

B. Durability Assessment Strand Woven Bamboo

A professional durability assessment strand woven bamboo involves examining both density and hardness. The extremely high density is directly correlated with a high Janka Hardness rating, often placing strandwoven bamboo well above popular tropical hardwoods. This makes the bamboo decking outdoor patio highly resistant to physical damage, indentation, and general wear and tear from foot traffic or patio furniture. This high density is a primary factor contributing to its robust, long-term performance.

III. Corrosion and Decay Resistance: The Role of Treatment

The term "corrosion" in wood and bamboo refers to biological decay (rot, mold, fungal attack), which thrives in moist, temperate conditions. Bamboo is naturally prone to decay because of its high starch and sugar content. This requires advanced processing to achieve true exterior durability.

A. Bamboo Patio Flooring Anti-Corrosion Treatment

The necessary bamboo patio flooring anti-corrosion treatment for strandwoven products involves a thermal modification process, typically high-temperature carbonization. During carbonization, the bamboo material is heated under controlled conditions, which leaches out the natural starches and sugars that feed mold and fungi. This process not only darkens the material but fundamentally alters its chemistry, making it biologically inert and drastically improving its resistance to rot and fungal attack—a crucial step for any bamboo decking outdoor patio exposed to rain and high humidity.

B. Bamboo Deck Resistance to Extreme Weather

The final bamboo deck resistance to extreme weather is determined by its resistance to moisture absorption. While carbonization improves biological resistance, the dense strandwoven structure itself minimizes water ingress. A comparison of moisture absorption:

| Decking Material | Processing Treatment | 24-Hour Water Absorption Rate (%) | Rot Resistance Rating |

|---|---|---|---|

| Untreated Bamboo | None | ~25% - 30% | Poor |

| Pressure-Treated Wood | Chemical Treatment | ~10% - 15% | Good |

| Strandwoven Bamboo | Thermal/Carbonized Treatment | < 5% | Excellent |

IV. Photodegradation and Surface Integrity

Long-term sun exposure causes photodegradation, where UV light breaks down the lignin structure in the bamboo, leading to surface graying, checking, and potential fiber weakening.

A. Outdoor Bamboo Decking UV Degradation Prevention

Effective outdoor bamboo decking UV degradation prevention relies entirely on the quality and regular maintenance of the surface finish. A clear or pigmented penetrating oil finish containing UV inhibitors is essential. This finish forms a protective layer, shielding the bamboo fibers from direct sunlight and minimizing the chemical breakdown of the lignin. Without regular re-oiling (typically every 1-2 years depending on exposure), any organic decking material, including high-performance strandwoven bamboo, will eventually turn a silvery-gray color due to photodegradation.

V. Quality Standards and Technical Sourcing for B2B

For wholesalers and B2B buyers, verifiable quality is paramount. Ningguo Kuntai Bamboo and Wood Co.,Ltd.'s commitment is underscored by our comprehensive certifications (ISO9001/14001, CE, SGS) and our US patent (No. US11148318) on outdoor bamboo decking. This patent signifies our proprietary manufacturing processes and product reliability, ensuring that every batch of bamboo decking outdoor patio is produced to a technically superior and consistently high standard, ready to meet the demands of global construction and design projects.

VI. Long-Term Performance of Strandwoven Bamboo

The question of durability for bamboo decking outdoor patio materials is answered by technology: the strandwoven process, combined with thermal modification, fundamentally alters bamboo to perform exceptionally under the stresses of long-term sun exposure, rain, and thermal cycling. By understanding the superior strandwoven bamboo decking temperature resistance and the necessity of proper bamboo patio flooring anti-corrosion treatment, buyers can confidently select a material that provides high mechanical stability and excellent biological resistance, validated through rigorous durability assessment strand woven bamboo.

VII. Frequently Asked Questions (FAQs)

Q1: How does strandwoven technology specifically improve the bamboo decking outdoor patio's durability?

- A: Strandwoven technology crushes and compresses the bamboo fibers and binds them with resin under high pressure and heat. This process creates an extremely dense product (>1,000 kg/m³) with very low porosity, which significantly increases Janka hardness, dimensional stability, and resistance to water absorption.

Q2: Is strandwoven bamboo decking temperature resistance better than wood? Why?

- A: Yes. Because strandwoven bamboo has extremely low absorption and a high-density, resin-bound structure, its swelling and shrinkage rates are much lower than most solid woods. This reduced volumetric change minimizes internal stress, greatly improving its resistance to warping and cracking during extreme temperature fluctuations.

Q3: What is the main purpose of the bamboo patio flooring anti-corrosion treatment (carbonization)?

- A: The main purpose is to remove the starches and sugars naturally present in the bamboo through high-temperature thermal modification. These sugars are the food source for mold and fungi, so removing them makes the material biologically inert and highly resistant to rot and decay.

Q4: What maintenance is required for outdoor bamboo decking UV degradation prevention?

- A: Regular re-application of a high-quality penetrating oil finish containing UV inhibitors is required (typically every 1-2 years, depending on sun exposure). Without this surface protection, the bamboo's lignin will break down from UV radiation, causing the decking to turn gray.

Q5: How does the durability assessment strand woven bamboo compare to pressure-treated wood?

- A: Strandwoven bamboo typically exhibits superior physical durability. It has a Janka hardness several times greater than pressure-treated softwood, providing much better resistance to indentation and physical wear. Furthermore, its low moisture absorption rate gives it excellent bamboo deck resistance to extreme weather and superior long-term dimensional stability.

English

English Deutsch

Deutsch

+86-572-5215066 5216895

+86-572-5215066 5216895 office@hh-bamboo.com

office@hh-bamboo.com East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.

East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.