- 1 Manufacturing Mastery: The Role of Strand Woven Technology

- 2 Thermal Modification: The Key to Hydroscopic Control

- 3 Controlling Size Fluctuation: Standards and Limits

- 4 Kuntai Bamboo and Wood: Leaders in Engineered Bamboo Materials

- 5 Frequently Asked Questions (FAQ)

- 5.1 1. What is the main technical benefit of the strand woven process for outdoor bamboo flooring?

- 5.2 2. What is the industry benchmark for Engineered bamboo deck planks EN 317 expansion limits in high-performance grades?

- 5.3 3. How does the Heat modification process for increasing bamboo durability specifically reduce water absorption?

- 5.4 4. Why is Swelling and shrinkage control in outdoor bamboo flooring more critical than for indoor flooring?

- 5.5 5. What does the Thermo-treated bamboo dimensional stability comparison reveal about its performance?

The success of **outdoor bamboo flooring** in demanding exterior environments hinges entirely on overcoming bamboo's natural hydroscopic tendencies—its propensity to absorb moisture and swell. Achieving genuine outdoor durability requires the synergistic application of advanced manufacturing techniques: high-pressure strand weaving to create density, and thermal modification (or carbonization) to chemically alter the cell structure. This dual approach ensures the material resists the relentless cycle of Swelling and shrinkage control in outdoor bamboo flooring caused by weather fluctuations.

Manufacturing Mastery: The Role of Strand Woven Technology

Strand Woven technology fundamentally changes the density and mechanical strength of the bamboo material.

Enhancing Durability via High-Pressure Strand Woven Process

- **Process:** Bamboo fibers are shredded, coated with exterior-grade resins (often phenolic), and compressed under extreme pressure (up to 1200 tons) and heat. This process achieves densities significantly higher than most hardwoods, typically ranging from 1050 to 1200 $\text{kg/m}^3$.

- **Result:** This immense density minimizes the internal voids where water typically infiltrates, drastically reducing overall moisture uptake. This initial mechanical densification is the first essential step in creating weather-resistant **outdoor bamboo flooring**.

Quantifying the Strand woven outdoor bamboo decking water absorption rate

The effectiveness of the strand woven process is quantified by the water absorption rate. Compared to standard solid bamboo (which can absorb 8-12% water after 24 hours immersion), high-density strand woven material drastically lowers this figure. Specialized testing reveals that properly engineered material minimizes the Strand woven outdoor bamboo decking water absorption rate to below 3% to 5% after 24 hours, confirming its superior closed-cell structure for exterior use.

Thermal Modification: The Key to Hydroscopic Control

Thermal treatment chemically stabilizes the bamboo cells, rendering them less attractive to moisture.

The Science of the Heat modification process for increasing bamboo durability

- **Mechanism:** Bamboo is heated in an oxygen-deprived environment (often 180°C to 230°C). This Heat modification process for increasing bamboo durability hydrolyzes the moisture-attracting hydroxyl groups ($\text{OH}$) within the bamboo's hemicellulose.

- **Benefit:** By chemically eliminating these groups, the material's equilibrium moisture content (EMC) is permanently lowered. This stabilization effect means the **outdoor bamboo flooring** reacts far slower and less dramatically to changes in ambient humidity.

Thermo-treated bamboo dimensional stability comparison with untreated bamboo

The performance differential is significant: Untreated bamboo absorbs and releases moisture readily, resulting in high volume changes. Thermo-treated bamboo, however, demonstrates superior resistance to moisture uptake. The Thermo-treated bamboo dimensional stability comparison shows that thermal modification reduces swelling and shrinkage by 40% to 60% compared to untreated or only standard carbonized bamboo.

Thermal Treatment Effect on Bamboo Properties Table

| Property | Untreated Strand Woven Bamboo | Thermo-Treated Strand Woven Bamboo |

|---|---|---|

| Equilibrium Moisture Content (EMC) | Higher (e.g., 8-10%) | Lower (e.g., 4-6%) |

| Dimensional Stability | Good, but prone to expansion | Excellent (Significantly improved) |

Controlling Size Fluctuation: Standards and Limits

International standards provide a benchmark for acceptable performance under humid conditions.

Technical Solutions for Swelling and shrinkage control in outdoor bamboo flooring

- **Multi-Step Approach:** Effective Swelling and shrinkage control in outdoor bamboo flooring requires combining thermal modification, high-density pressing, and the use of exterior-grade binding resins. The thermal modification addresses the internal fiber structure, while the high pressure and resin address the macro-level porosity.

Adhering to Engineered bamboo deck planks EN 317 expansion limits

The European Standard EN 317 (which measures thickness swelling after water immersion) provides a reliable indicator of dimensional stability. For standard interior wood-based panels, this limit is often around 10-14%. However, for high-performance Engineered bamboo deck planks EN 317 expansion limits must be significantly lower to guarantee exterior performance. Industry best practice for premium strand woven bamboo requires the thickness swelling rate to be controlled to less than 2% to 3% after 24 hours of total immersion, ensuring minimal movement and warp in service.

Kuntai Bamboo and Wood: Leaders in Engineered Bamboo Materials

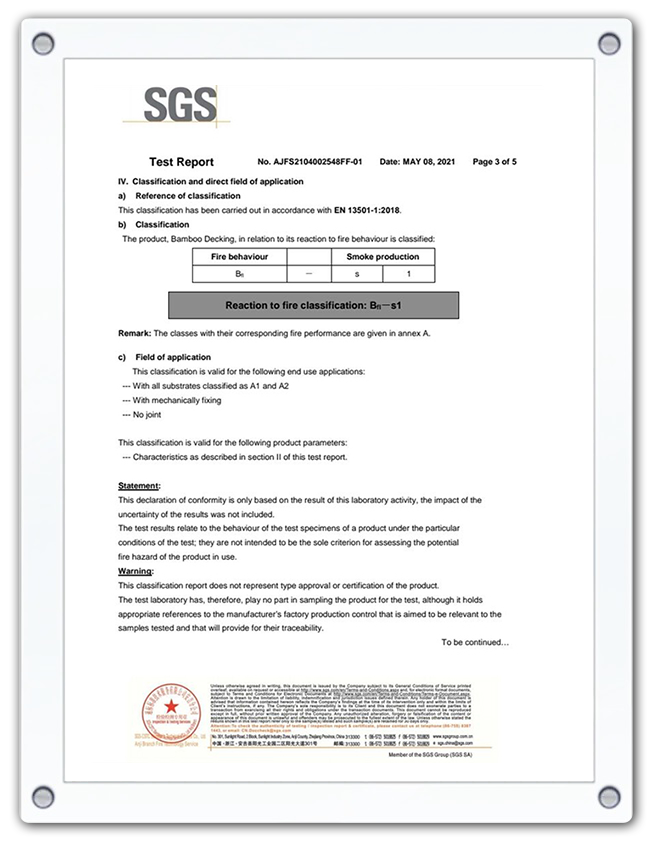

Ningguo Kuntai Bamboo and Wood Co.,Ltd., located in the heart of China's "Bamboo Village," has been specializing in bamboo material innovation since 2002. Our modern KUNTAI factory, covering 30,000 square meters, focuses on the professional manufacturing of high-performance **outdoor bamboo flooring**, decking, and cladding. We utilize the precise **Heat modification process for increasing bamboo durability** combined with high-pressure strand weaving to ensure our products meet the stringent requirements for exterior use, including achieving the low Strand woven outdoor bamboo decking water absorption rate necessary for long service life. Holding certificates such as FSC, CE, and ISO, and possessing a US patent (No. US11148318) for outdoor bamboo decking, KUNTAI provides reliable, stable, and certified solutions that excel in Thermo-treated bamboo dimensional stability comparison tests against competitors, offering superior Swelling and shrinkage control in outdoor bamboo flooring for global projects.

Frequently Asked Questions (FAQ)

1. What is the main technical benefit of the strand woven process for outdoor bamboo flooring?

The main technical benefit is drastically increased density (up to $1200 \text{ kg/m}^3$), which closes the internal cell structure, significantly reducing porosity and minimizing the water absorption rate compared to standard bamboo or wood.

2. What is the industry benchmark for Engineered bamboo deck planks EN 317 expansion limits in high-performance grades?

While standard wood limits are higher, premium engineered bamboo deck planks should target a thickness swelling rate of less than 2% to 3% after 24 hours of water immersion, demonstrating superior dimensional stability.

3. How does the Heat modification process for increasing bamboo durability specifically reduce water absorption?

The heat modification process chemically hydrolyzes the moisture-attracting hydroxyl ($\text{OH}$) groups in the bamboo's hemicellulose, permanently lowering the material's equilibrium moisture content (EMC) and making it less hydroscopic.

4. Why is Swelling and shrinkage control in outdoor bamboo flooring more critical than for indoor flooring?

It is more critical because outdoor materials are exposed to much wider and more frequent variations in temperature and humidity, which require exceptional dimensional stability to prevent warping, cupping, and cracking.

5. What does the Thermo-treated bamboo dimensional stability comparison reveal about its performance?

The comparison reveals that thermo-treated bamboo exhibits up to 60% less swelling and shrinkage than untreated bamboo, making it vastly superior for long-term outdoor exposure and a more reliable building material.

English

English Deutsch

Deutsch

+86-572-5215066 5216895

+86-572-5215066 5216895 office@hh-bamboo.com

office@hh-bamboo.com East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.

East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.