- 1 Material Engineering: Why Strand-Woven Bamboo Excels in Humidity

- 2 Stability Comparison: Bamboo vs. Composite in Tropical Climates

- 3 Technical Compliance and B2B Specification Standards

- 4 Application and Safety: Beyond the Surface

- 5 Conclusion: The Engineering Verdict for Humid Regions

- 6 Frequently Asked Questions (FAQ)

Selecting the ideal material for external surfacing in tropical or coastal regions requires a deep understanding of hygroscopic behavior and biological resistance. Historically, Ipe or Teak were the standard for premium projects, but modern engineering has positioned bamboo flooring outdoor decking as a technically superior alternative. Ningguo Kuntai Bamboo and Wood Co., Ltd., located in the "Bamboo Village" of Ningguo, Anhui Province, has been at the forefront of this innovation since 2002. Operating from a 30,000-square-meter modern factory, KUNTAI produces high-performance outdoor strandwoven bamboo decking, wall-cladding, and ceiling systems. As the holder of a US patent for outdoor bamboo decking (No. US11148318), we provide B2B clients with specialized solutions that withstand the rigors of extreme humidity.

Material Engineering: Why Strand-Woven Bamboo Excels in Humidity

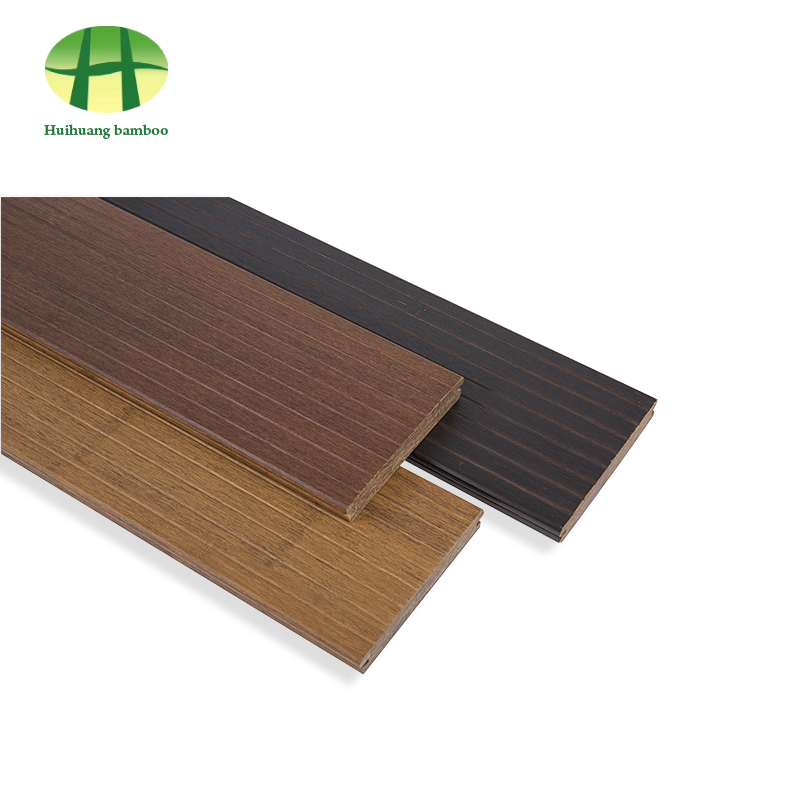

The superior performance of bamboo flooring outdoor decking stems from its manufacturing process. Unlike solid timber, which retains its natural cellular pores, strand-woven bamboo involves shredding the fibers and re-compressing them under extreme pressure with phenolic resins. This densification creates a material with a density of approximately 1,150 kg/m³, making it nearly impervious to water ingress. According to the international standard ISO 5942:2024, high-performance bamboo-based engineered materials must maintain strict moisture content ranges between 6% and 12% to ensure bonding durability in structural applications.

Source: ISO 5942:2024 Bamboo-wood composite for container flooring — Specifications

Comparison: outdoor strandwoven bamboo decking durability vs. Tropical Hardwood

While exotic hardwoods like Ipe are naturally dense, they are prone to checking and splintering when subjected to the rapid wet-dry cycles typical of high-humidity climates. In contrast, strand-woven bamboo provides a more uniform internal structure that resists internal stresses better than natural grain patterns.

| Feature | Exotic Hardwood (e.g., Ipe) | Strand-Woven Bamboo |

| Janka Hardness | Approx. 3,600 lbf | Exceeds 3,800 lbf |

| Moisture Absorption | Moderate; leads to surface checking. | Ultra-low; stabilized by resin encapsulation. |

| Biological Resistance | Naturally high but variable by batch. | Consistently high due to thermal treatment. |

Stability Comparison: Bamboo vs. Composite in Tropical Climates

Wood-Plastic Composites (WPC) are often marketed for their low maintenance, but they face significant challenges in high-heat and high-humidity environments. Composites have a high coefficient of thermal expansion, causing them to "sag" between joists or buckle if not installed with massive gaps. low maintenance bamboo outdoor deck boards, however, behave more like carbon-fiber-reinforced polymers. They maintain structural rigidity even when surface temperatures exceed 40°C. Market data for 2025 indicates that the global bamboo decking market is growing at a CAGR of 3.6%, largely driven by the construction industry's shift toward materials that combine the aesthetics of wood with the stability of high-tech composites.

Source: Global Bamboo Decking Market Size & Share Analysis 2025-2032

Comparison: Dimensional Stability of low maintenance bamboo outdoor deck boards vs. WPC

Bamboo exhibits significantly less thermal movement than plastic-based composites, allowing for tighter gaps and a more premium aesthetic in large-scale decking projects.

| Property | WPC (Composite) | Strand-Woven Bamboo |

| Thermal Expansion | High; requires 5-8mm gaps. | Low; stable dimensions across seasons. |

| Static Load Capacity | Prone to "creep" (permanent sagging). | Excellent; high modulus of elasticity. |

| Heat Retention | High; can burn bare feet in summer. | Moderate; natural fiber dissipation. |

Technical Compliance and B2B Specification Standards

For large-scale commercial procurement, the technical pedigree of the supplier is non-negotiable. It is critical to partner with FSC certified bamboo decking manufacturers in China to ensure both environmental sustainability and rigorous quality control. KUNTAI holds certificates for FSC, CE, SGS, and ISO9001/14001, providing the necessary documentation for international bidding. The recent release of ISO 7567:2024 further standardizes the requirements for glued laminated bamboo in structural use, ensuring that B2B buyers can specify bamboo for bridges, ceilings, and heavy-duty flooring with absolute confidence in its load-bearing parameters.

Source: ISO 7567:2024 Bamboo structures — Glued laminated bamboo — Product specifications

Application and Safety: Beyond the Surface

In public infrastructure, safety ratings are as important as durability. A fire rated bamboo wall cladding for commercial projects ensures that facades meet strict building codes (such as Class A or B1 ratings) while providing the natural warmth of timber. For boardwalks and public plazas, high density strand woven bamboo planks for high traffic offer slip resistance and an incredible lifespan, often backed by 20-25 year warranties against rot and structural failure.

Conclusion: The Engineering Verdict for Humid Regions

When engineering outdoor spaces in high-humidity climates, bamboo flooring outdoor decking offers the most balanced profile of durability, stability, and aesthetic value. By utilizing the proprietary strand-weaving technology found at Kuntai's Anhui facility, developers can achieve a finish that outlasts hardwood and out-performs composite. As a US patent holder and professional manufacturer, Kuntai invites global partners to visit our "Bamboo Village" factory to witness the intersection of nature and advanced material science.

Frequently Asked Questions (FAQ)

- Does bamboo flooring outdoor decking rot in the rain? No, high-quality strand-woven bamboo undergoes a thermal modification process that removes sugars and starches, making it naturally resistant to rot, mold, and termites.

- How often does low maintenance bamboo outdoor deck boards need oiling? Typically once a year to maintain the deep color; however, its structural integrity remains intact even if allowed to weather to a natural silver-grey.

- Is it hard to install high density strand woven bamboo planks for high traffic? Installation is similar to hardwood; however, because of its extreme density, high-quality carbide-tipped tools and pre-drilling are recommended.

- Why should I look for FSC certified bamboo decking manufacturers in China? FSC certification ensures the bamboo is harvested from responsibly managed forests, which is a key requirement for LEED and BREEAM-certified green building projects.

- Is fire rated bamboo wall cladding for commercial projects safe for high-rises? Yes, specialized treatments allow our bamboo cladding to achieve high fire-safety ratings suitable for exterior facades in urban environments.

English

English Deutsch

Deutsch

+86-572-5215066 5216895

+86-572-5215066 5216895 office@hh-bamboo.com

office@hh-bamboo.com East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.

East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.