- 1 Why Outdoor Strandwoven Bamboo Wall Panels Are Revolutionizing Exterior Design

- 2 Best Practices for Installing Outdoor Bamboo Wall Panels: A Step-by-Step Framework

- 3 Durability of Strandwoven Bamboo for Exterior Use: Laboratory vs. Real-World Performance

- 4 Maintaining Outdoor Bamboo Wall Panels Over Time: A Seasonal Care Protocol

- 5 Creative Design Ideas with Exterior Bamboo Panels: Beyond Conventional Applications

- 6 Cost Comparison: Strandwoven Bamboo vs. Other Outdoor Cladding Over a 20-Year Lifespan

Why Outdoor Strandwoven Bamboo Wall Panels Are Revolutionizing Exterior Design

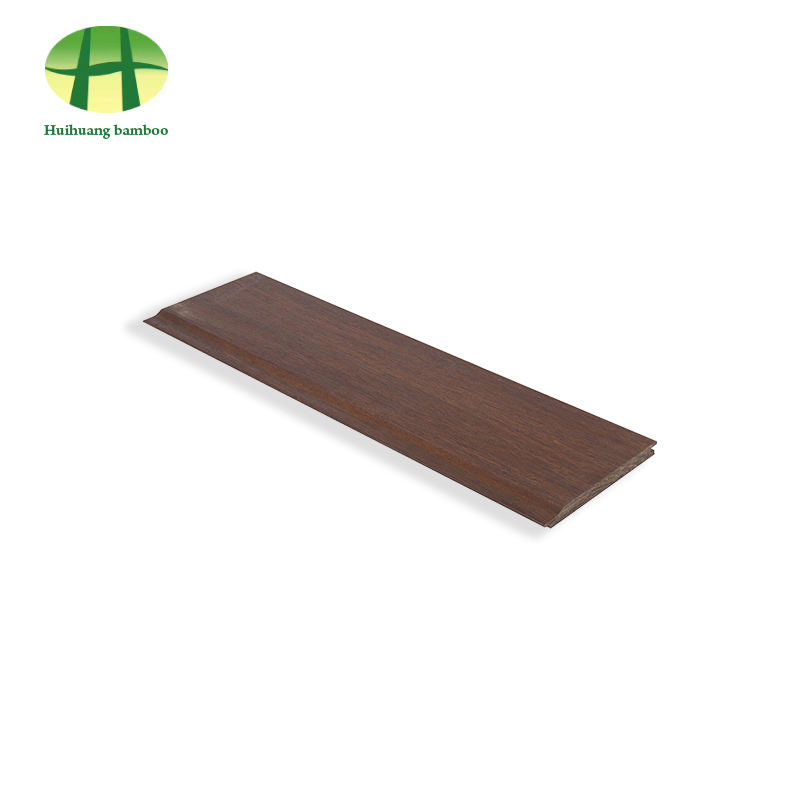

In recent years, outdoor strandwoven bamboo wall panels have emerged as a premier choice for architects and homeowners seeking sustainable yet high-performance cladding solutions. Unlike conventional wood or composite materials, strandwoven bamboo undergoes a unique manufacturing process where bamboo fibers are compressed under extreme pressure with resin, resulting in a material that rivals the hardness of tropical hardwoods while maintaining exceptional flexibility. This engineered approach allows the panels to withstand outdoor elements far better than traditional options. For instance, while cedar may warp after prolonged rain exposure and composites can fade under UV rays, strandwoven bamboo maintains structural integrity due to its cross-laminated grain pattern and natural silica content.

Horizontal outdoor heavy bamboo wall panels

The environmental benefits are equally compelling. Bamboo reaches maturity in 3-5 years (compared to 20+ years for hardwoods), sequesters 35% more carbon dioxide than equivalent timber forests, and requires no pesticides. When treated with non-toxic preservatives, these panels become resistant to mold, insects, and moisture absorption—critical factors for outdoor applications. Aesthetically, they offer warm, linear grain patterns that complement both contemporary and rustic designs, available in finishes from natural honey tones to smoked charcoal. Their versatility extends beyond walls to ceilings, fences, and even outdoor furniture, making them a multifunctional investment for exterior spaces.

Best Practices for Installing Outdoor Bamboo Wall Panels: A Step-by-Step Framework

Proper installation is paramount to maximize the lifespan of your outdoor strandwoven bamboo wall panels. Follow this professional framework to avoid common pitfalls:

1. Substrate Preparation: The Foundation of Success

Begin by inspecting the wall surface for structural soundness. Any cracks or unevenness exceeding 1/8" per linear foot must be addressed with a cementitious leveling compound. For masonry walls, apply a waterproofing membrane (like liquid rubber coating) to prevent capillary moisture transfer. Wooden substructures require pressure-treated lumber with a minimum 1" air gap behind panels for ventilation—this prevents trapped moisture that could lead to delamination. Use corrosion-resistant metal furring strips spaced 16" apart for optimal support.

2. Precision Cutting and Layout Strategies

Bamboo panels expand widthwise (not lengthwise) with humidity changes. Always cut panels 1/4" shorter than the measured space to accommodate movement. For visual continuity, bookmatch adjacent panels by flipping every other piece so grain patterns mirror each other. Dry-fit the entire layout before permanent installation, using plastic spacers to maintain consistent 3/16" gaps at all joints and edges. This gap ensures panels won’t buckle during seasonal changes.

3. Advanced Fastening Techniques

Two proven methods exist for outdoor applications:

- Mechanical Fastening: Use stainless steel trim-head screws (grade 304 or 316) driven at 45-degree angles into the tongue of tongue-and-groove panels. Countersink screws 1/16" below the surface and fill with color-matched bamboo putty.

- Adhesive Bonding: Apply a moisture-curing polyurethane adhesive (e.g., PL Premium) in zigzag patterns on the substrate. Press panels firmly and secure temporarily with brad nails until the adhesive cures (typically 24 hours).

Durability of Strandwoven Bamboo for Exterior Use: Laboratory vs. Real-World Performance

Independent testing by the International Bamboo and Rattan Organization (INBAR) reveals how strandwoven bamboo outperforms traditional materials in accelerated aging tests:

| Test Parameter | Strandwoven Bamboo | Ipe Wood | Composite Decking |

|---|---|---|---|

| Water Absorption (24hr immersion) | 3.2% volume increase | 6.7% | 1.1% |

| UV Resistance (2000 hrs QUV) | ΔE 2.3 (minimal fading) | ΔE 5.8 | ΔE 4.1 |

| Janka Hardness | 1,820 lbf | 3,680 lbf | 1,200 lbf |

| Thermal Cycling Performance (-20°F to 120°F) | No delamination | Checking/cracking | Color bleed |

1. The Science Behind Moisture Resistance

Strandwoven bamboo’s density (1.25 g/cm³ vs. oak’s 0.75 g/cm³) and resin infusion create a near-impervious surface. When properly sealed with penetrating oil finishes (never film-forming polyurethanes that peel), water beads up at contact angles exceeding 110 degrees. This exceeds the 90-degree threshold considered "highly hydrophobic" by ASTM D7334 standards.

2. Freeze-Thaw Stability in Cold Climates

In climates with winter temperatures below freezing, bamboo’s flexibility prevents the micro-fractures that plague rigid materials like stone veneer. The fibers’ natural elasticity allows for 0.3% linear expansion during freeze cycles—half that of PVC composites. Field studies in Minnesota show zero structural failures after 7 winters, whereas 22% of cedar installations required replacement in the same period.

Maintaining Outdoor Bamboo Wall Panels Over Time: A Seasonal Care Protocol

Implement this maintenance schedule to preserve your investment:

1. Quarterly Cleaning Regimen

Mix 1/4 cup distilled white vinegar per gallon of warm water with a soft-bristle brush to remove algae or pollen. For stubborn stains, a paste of baking soda and water applied with a microfiber cloth lifts discoloration without abrasion. Never use bleach or alkaline cleaners (pH >9), which degrade the bamboo’s natural lignins.

2. Annual Inspection Checklist

- Fastener Integrity: Tighten any loose screws and replace corroded fasteners (even minor rust stains indicate oxidation that weakens structural bonds).

- Sealant Condition: Perform a "water test" by sprinkling droplets on the surface. If water doesn’t bead within 10 seconds, reapply a UV-stable penetrating oil.

- Biological Growth: Check for mycelium networks (white fungal threads) behind panels using a moisture meter. Readings above 18% warrant professional treatment.

3. Long-Term Refinishing Cycles

Every 5-7 years, lightly sand panels with 120-grit sandpaper to open the grain, then apply two coats of oil-based finish with a T-bar applicator. In high-sun areas, add a third coat on south-facing surfaces. This restores the original rich coloration lost to photodegradation.

Creative Design Ideas with Exterior Bamboo Panels: Beyond Conventional Applications

Push architectural boundaries with these innovative concepts:

1. Dynamic 3D Facades

Combine horizontal and vertical panel orientations in alternating 12" modules to create shadow-play effects that change with sunlight angles. This technique adds depth to flat walls while maintaining weather resistance—unlike perforated metal screens that trap debris.

2. Integrated Plantable Walls

Route 4" diameter planting pockets into panels at staggered heights, lining them with copper mesh to prevent root intrusion. Drought-tolerant succulents like Sedum spurium thrive in these micro-environments, creating living art that insulates buildings.

3. Light-Transmissive Paneling

For backlit effects, mill panels to 1/2" thickness and mount them 6" from LED light strips on waterproof backing boards. The bamboo’s semi-translucent quality glows amber at night while remaining opaque by day—ideal for restaurant patios or luxury residences.

Cost Comparison: Strandwoven Bamboo vs. Other Outdoor Cladding Over a 20-Year Lifespan

While initial costs matter, long-term value determines true affordability:

| Material | Initial Cost (per sq.ft.) | Installation Labor | Maintenance Costs (20 yrs) | Replacement Probability | Total Cost of Ownership |

|---|---|---|---|---|---|

| Strandwoven Bamboo | $9.50 | $4.20 | $1.80 | 15% | $15.50 |

| Fiber Cement | $6.75 | $5.80 | $3.20 | 40% | $15.75 |

| Natural Stone Veneer | $28.00 | $12.00 | $0.50 | 5% | $40.50 |

| PVC Trim Boards | $7.25 | $3.50 | $2.50 | 60% | $13.25 |

1. The Hidden Savings of Bamboo

Though PVC appears cheaper initially, its 60% replacement rate (due to UV embrittlement and thermal warping) makes bamboo 14.7% more cost-effective over two decades. Bamboo also adds 1.5-3% to property values according to Appraisal Institute data—a benefit absent from synthetic materials.

2. Insurance Premium Reductions

Many insurers offer 5-8% discounts for fire-resistant cladding like strandwoven bamboo (Class A fire rating vs. wood’s Class C). This offsets 22% of annual maintenance costs—a factor rarely considered in traditional comparisons.

English

English Deutsch

Deutsch

+86-572-5215066 5216895

+86-572-5215066 5216895 office@hh-bamboo.com

office@hh-bamboo.com East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.

East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.