Introduction

When it comes to creating a durable, attractive outdoor living space, the process of Bamboo composite decking installation plays a pivotal role. Choosing the right product and executing a professional installation ensures longevity, aesthetics and performance. This guide is designed to help you make smart decisions during procurement and understand the expert steps to complete installation correctly.

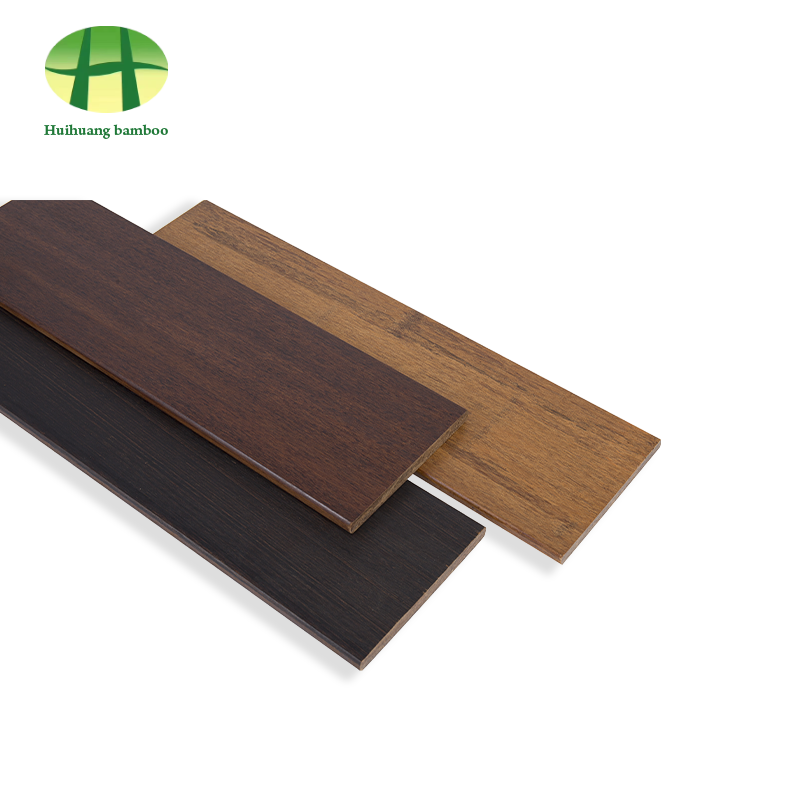

Custom size glossy heavy bamboo flooring

Step 1: How to Choose the Right Product for Your Project

1. Understand the material — composition & structure

- Bamboo composite decking is typically made from rapid‑growth bamboo fibres combined with durable binders or plastics.

- This combination blends the natural look of bamboo with enhanced durability and weather‑resistance.

- Compared with traditional wood or pure WPC (wood‑plastic composite), the material offers unique advantages in aesthetics and sustainability.

2. Compare solid vs hollow boards

One of the essential considerations is whether to select solid‑core or hollow‑core boards for your deck. Below is a comparison:

| Feature | Solid Board | Hollow Board |

| Weight & material use | Heavier, more material used | Lighter, less material |

| Load‑bearing & impact resistance | Higher, more suitable for heavy furniture/high traffic | Lower, better for lighter use |

| Cost | Generally higher | Generally lower |

| Thermal & sound insulation | Less insulation | Better insulation due to cavity |

| Recommended setting | Large patios, high traffic | Balconies, lighter garden decks |

By assessing this comparison, you can decide whether to go with a solid board or hollow board for your deck based on your requirements.

3. Evaluate load, environment & use case

- Ask yourself: will the deck be part of a larger patio, a rooftop terrace, or a simple garden walkway?

- If you are specifically choosing bamboo composite decking for outdoor patio usage, consider exposure to sunlight, humidity, poolside splash areas, and expected foot traffic.

- Boards for high traffic or heavy furniture should favour stronger specifications and closer joist spacing.

4. Check certifications & manufacturer credentials

- Ensure the manufacturer holds proper certifications (e.g., FSC, CE, ISO 9001, ISO 14001) and possibly patents, which indicate manufacturing control and product reliability.

- As an example, our company, Ningguo Kuntai Bamboo and Wood Co., Ltd., located in Ningguo (Xuancheng City, Anhui Province, "Bamboo Village"), has established a 30,000 m² modern factory and holds FSC, CE, SGS and ISO certifications; we also hold a U.S. patent for outdoor bamboo decking (No. US11148318) as an authorised manufacturer/exporter in China. This background helps ensure trust in product quality and supply chain transparency.

5. Budgeting & preliminary cost considerations

- When planning your installation, include material cost, substructure (joists, supports), fasteners/clips, labour, waste allowance (typically 5‑10%) and finishing touches.

- By thinking ahead about bamboo composite decking installation cost and preparation, you'll avoid surprises and budget overruns.

- Request quotes for all key components and anticipate extra cost for complex layouts or site conditions (slope, drainage, retrofits).

Step 2: Preparation Before Installation

1. Site inspection & substructure check

- Ensure the base is level, well‑drained and firmly supported. Standing water or poor ventilation under the deck can reduce lifespan.

- Check existing structure (if retrofitting) for rot, instability or inadequate joist support. Replace or reinforce as needed.

2. Tools & materials required

- Standard woodworking tools: circular saw (carbide‑tipped blade), drill, tape measure, level, chalk line, safety gear.

- Fasteners/clips suited for outdoor use (stainless steel, corrosion‑resistant), spacers for expansion gaps, edge trims if needed.

3. Board acclimation & layout planning

- Allow the boards to acclimate in the installation environment for 24‑48 hours to reduce later warping.

- Create a layout plan: board direction, pattern, start row, cutting strategy. Order ~10% extra for waste and cutting loss.

4. Safety & regulatory compliance

- Wear safety glasses, gloves, dust mask and follow local building codes.

- Ensure permits are obtained if required and that the installation meets load, fire rating or zoning regulations for your region.

Step 3: Professional Installation Process for Bamboo Composite Decking

1. Installing joists and sub‑frame

- Set joist spacing per board specification: often 12″–16″ on centre for heavier boards.

- Ensure joists are level, perpendicular to deck boards, and supported by concrete footings or suitable sub‑structure.

2. Laying first boards & using fasteners/clips

- Install starter clips or face screws for the first row. Predrill near board ends and secure to each joist.

- Use hidden fasteners in the grooves where available to maintain clean surface appearance. Tighten at correct torque and avoid over‑tightening.

3. Solid vs hollow board installation differences

- With solid boards: heavier weight means careful handling, ensure strong sub‑frame and allow for minimal sagging.

- With hollow boards: lighter weight but may require closer joist spacing or extra support under high load zones.

- These are key solid vs hollow bamboo composite decking installation tips that differentiate your approach based on board type.

4. Expansion gaps, trimming, end treatment

- Leave appropriate expansion gap between boards and at butt ends (typically 3 mm–5 mm or per spec).

- Trim final boards to fit, and seal cut ends if required by the manufacturer to prevent moisture ingress.

5. Finishing touches and quality check

- Check entire surface for level, tight fasteners, board alignment, visible defects.

- Install fascia or edge trims, clean debris from joist cavities, and ensure deck slopes slightly for drainage if required.

Step 4: Post‑Installation Maintenance & Longevity

1. Routine cleaning and care

- Sweep regularly to remove leaves, dust and debris. These can trap moisture and cause staining.

- Use mild soap and warm water for cleaning; avoid high‑pressure washers unless specified safe by board manufacturer.

2. Seasonal inspection & repairs

- Periodically inspect board joints, fasteners, signs of warping or compression. Address issues early.

- Ensure sub‑frame ventilation remains clear, and that water is not pooling beneath the deck.

3. Common issues and troubleshooting

- Fading or lightening of colour over time — can be mitigated by coatings or oiling if permitted.

- Board deformation — often due to inadequate joist spacing or missing expansion gaps.

- Surface scratches or gouges — treat per manufacturer guidelines.

4. Why maintenance matters for your bamboo composite deck

If you want your investment in Bamboo composite decking installation to deliver long‑term value, then maintenance is not optional. The right maintenance plan supports durability, aesthetics and performance. This is particularly true when you factor in maintenance after bamboo composite decking installation outdoors, where exposure to weather is greater.

Conclusion

Properly selecting the right bamboo composite decking product and executing a professional installation are both essential to achieving a beautiful, durable outdoor deck. By following the procurement steps — from material understanding and board type selection to certifications and budgeting — you set a strong foundation. Then by preparing the site, installing with expertise, and maintaining the deck over time, you safeguard your outdoor investment. Leveraging the expertise of a reputable manufacturer like Ningguo Kuntai Bamboo and Wood Co., Ltd. — with its substantial factory, certifications and patent backing — further enhances your confidence in the outcome.

FAQ

- Q1: What is the best board type for a high‑traffic outdoor deck?

A: For high traffic, heavy furniture or commercial use, a solid board type is generally preferred over a hollow board because of its higher load resistance and stability. - Q2: Can I install bamboo composite decking myself?

A: Yes, you can—but ensure you follow detailed installation steps for Bamboo composite decking installation and verify the subframe, joist spacing, and fastener system are correct. - Q3: How much extra material should I order for waste and cutting?

A: It's wise to order approximately 5 %–10 % extra material to account for cuts, waste, mistakes and off‑cuts. - Q4: How often should I maintain my deck after installation?

A: At minimum, sweep regularly, wash with mild soap annually, inspect fasteners and boards seasonally — this supports long‑term performance of your deck after maintenance after bamboo composite decking installation outdoors. - Q5: What should I check for when choosing a manufacturer?

A: Look for certifications (FSC, CE, ISO), warranty terms, manufacturing facility scale (such as 30,000 m² factory), and whether they hold patents for outdoor decking use. This ensures you select a reliable supplier.

English

English Deutsch

Deutsch

+86-572-5215066 5216895

+86-572-5215066 5216895 office@hh-bamboo.com

office@hh-bamboo.com East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.

East Side of Huanggang RD,Ningdun County, Ningguo ,Xuancheng City,Anhui Province,China.